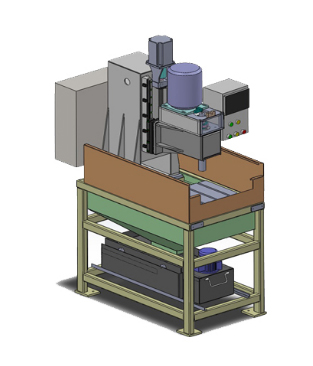

Facing Centering Machine

STANDARD FEATURES

Steel fabricated stress relived find machined and grounded bed

Precisely machined bore honed facing head

Cartridge type grounded and chrome plated quill

Spindle Precision heavy duty tapper roller bearings front and rear

Fine machined scrapped facing head slides with position lock pads

One side Slide rack and pinion arrangements to adjust the slide position

Precision Quill lock nuts provided to set the part length +-0.1 mm precision

Hydraulic screw type self centering vice with hardened clamping pads

Facing Tool holder with adjustable centering , facing tool cartridges

Through coolant spindle

Centralized auto lubrication

Standard hydraulic power pack and electrical panel

Necessary sheet metal covers

| Description | RVFC500 | RVFC1000 | RVFC1500 |

|---|---|---|---|

| Bar facing dia max in mm | 65mm | 65mm | 65mm |

| Bar length min to max in mm | 100 to 500 | 100 to 1000 | 100 to 1500 |

| Centre drill size | BS3 to BS6 | BS3 to BS6 | BS3 to BS6 |

| No of spindle head | 2 | 2 | 2 |

| Facing and centring tool holder | 2 | 2 | 2 |

| Bar min max dia in two vice | 20 to 125 | 20 to 125 | 20 to 125 |

| Spindle Power LH and RH in KW | 2.2 | 2.2 | 2.2 |

| Spindle RPM | 750mm | 750mm | 750mm |

| Quil travel in mm (hyd) | 40mm | 40mm | 40mm |

| Machine dimension (LXBXH) | 575 x 715 x 1700mm | 575 x 715 x 1790mm | 575 x 715 x 2035mm |

| Lubrication | Centralised Lubrication system | Centralised Lubrication system | Centralised Lubrication system |

| coolant system | Through coolant system | Through coolant system | Through coolant system |

| Machine dimensions LBH in mm | 1500 x1200 x1600 | 2000 x 1200 x 1600 | 2500 x 1200 x1600 |

| Total power in | 8kw/440v | 8kw/440v | 8kw/440v |