PITCH CONTROL TAPPING MACHINE

| Description | RVT8CG | RVT16CG | RVT30CG |

|---|---|---|---|

| Max. drilling capacity in steel (400N/mm) | M3 - M8 | M8 - M16 | M10 x 1.5P - M30x3.5P |

| Spindle type | PB 16/ER16 | PB 20/ER20 | PB 28 |

| Spindle Power in kw | 0.37 /1440 | 0.75/720rpm | 1.5 |

| Speed range in rpm | 420,760,1340 | 155/285/515 | 200,100,50 |

| Pitch Range in TPI | 32,28,27,24,20,19,18, 16, 14,13,12,11,10 | 32,28,27,24,20,19,18, 16, 14,13,12,11,10 | 16,14,13,12,11,10,9,8,7,6 |

| Quill Travel in mm | 60 | 65 | 65 |

| Distance between spindle center to column in mm (Approx) | 220 | 280 | 300 |

| Spindle to table min /max in mm (Approx) | 100 -350 | 100 -450 | 100 -450 |

| Table size in mm | 300 x 260 | 330 x 330 | 360 x 340 |

| Machine dim ( L x B x H) in mm (Approx) | 600x 750 x 1000 | 675 x 865 x 1200 | 675 x 865 x 1200 |

| Machine weight in kg | 270 | 300 | 330 |

Percision Pitch Control Through Gears

Pitch Control gears feed the tap at the rate of one thread per revolution, with repeatability of stroke within 1/5 pitch of thread.Compared to leadscrew drive,change gears wear less.There is no reverse cut or pulling force during return stroke of the spindle thus ensuring smooth finish.

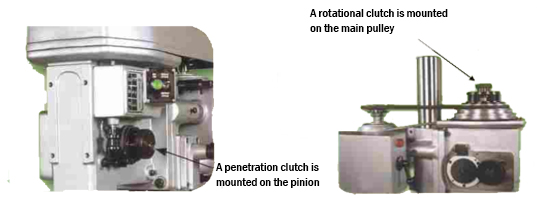

Work Piece and Tool Safety

A dual clutch system prevents tool breakage in case of spindle overload due to undersized or missing holes.

STANDARD FEATURES

Can be mounted multi spindle Tapping head

Adjustable quill travel length

Precisely bored, coned, plated quill bore Grounded plated quill

Grounded plated quill

Hardened and grounded spindle Thread grounded spindle

Thread grounded spindle

Spindle nose thread grounded for repeated and easy tool changing

Adjustable column for wide range fixture accommodation

Ideal for productivity through multi spindle drilling and single drilling

Graded cast iron housing fine machined and bored Dual clutch system prevents tap breakage,

Wide range inch and mm tapping possible by changing gears

OPTIONAL FEATURES

Machine cabinet

Machine Stand

Peck Tapping attachment

Electrical panel

Coolant system

Pneumatic linear table attachment